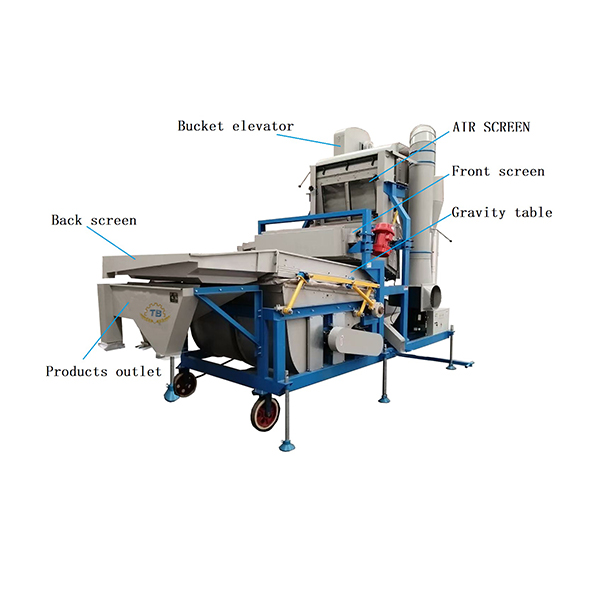

The vibrating iska allon tsabtace aka yafi hada da wani frame, a ciyar na'urar, wani allo akwatin, wani allo jiki, a allo tsaftacewa na'urar, a crank haɗa sanda tsarin, a gaba tsotsa bututu, a raya tsotsa bututu, wani fan, karamin allo, a gaban sett room, a raya sett room, a najasa cire tsarin, da iska kamar daidaitawa tsarin. Na'ura da aka kafa ta hanyar haɗa fanti da na'urar tantancewa ta jiki tana amfani da girman halayen tsaba don tantancewa da halayen iska na iri don rabuwar iska. Ana amfani da shi sosai a wuraren haƙora, ma'adinai, kayan gini, ma'adinan kwal, filayen yaƙi da sassan sinadarai don rarraba kayan aiki.

Motsi na mai tsaftar iska mai girgiza shine cewa motar tana fitar da mai motsi tare da babban taro ta hanyar V-belt, don haka gadon allo yana girgiza lokaci-lokaci da asymmetrically, don abin da ke saman allo yana kwance kuma an watsar da shi daga saman allo, don ingantaccen abu zai iya faɗuwa ta cikin Layer na kayan kuma a rabu ta cikin rami na allo, kuma ramin yana da ƙarfi a cikin ramin allo. fitarwa ta allon.

Siffofin samfur na tsabtace allon iska mai girgiza;

1. Firam ɗin yana ɗaukar cikakken tsari mai haɗuwa, wanda ya dace don sufuri da shigarwa.

2. The vibration exciter rungumi dabi'ar Silinda ko wurin zama toshe eccentric tsarin, da kananan allon rungumi dabi'ar Silinda lubricating man don kai lubrication, da kuma babban allo rungumi dabi'ar wurin zama circulating man ga lubrication.

3. Dukkanin haɗin gwiwa na gadon sieve an haɗa su ta hanyar ƙarfin ƙarfi na tsarin karfe. Ana amfani da ƙarfe na musamman na manganese don haɗar ƙirar shigarwa na tashin hankali na sieve, wanda yake da sauƙi kuma mai dacewa don maye gurbin sieve kuma yana da tsawon rayuwar sabis.

4. Yi amfani da fasahar murƙushe ƙananan murƙushewa don rage murkushe masara yayin masussuka.

5. Cikakken tsaftacewa ta hanyar rabuwa da iska da nunawa yana tabbatar da tsaftacewa zuwa matsakaicin.

6. Sakamakon yana da girma, kuma guda ɗaya na iya saduwa da bukatun samar da dukkanin layin samarwa.

Lokacin aikawa: Fabrairu-02-2023